|

|

||||||||||||||||||||||

|

| russian |

|

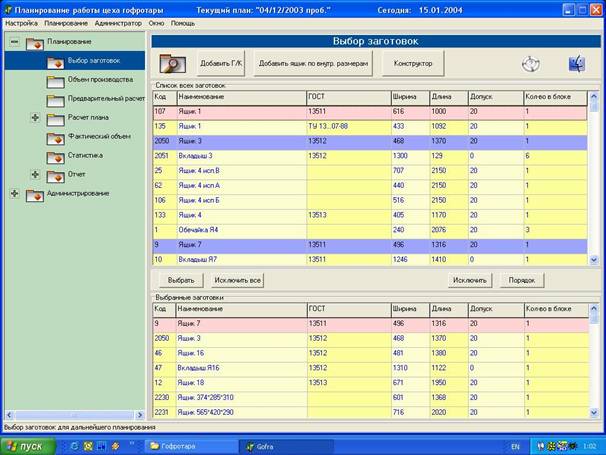

Software system "ASC: Corrugated cardboard"Key factsArkhangelsk pulp-and-paper mill is one of 10 largest mills in Russia. At the cardboard cutting plant of the mill the 2.1-meter wide cardboard line is cut into rectangular pieces at the speed of 160 m/min. The pieces are used for making boxes. The plant operators' task is to ensure the production of required number of boxes, made of several rectangles of different size. The challengeAs the number of different types of boxes has grown to 100 per week, and the number of boxes of each type went down to few thousand, the material losses have dramatically increased to 5-6%. The human mind was unable to review all possible combinations of rectangles of required sizes, and choose the one that would yield the least trim. Also time for re-tuning of the finishing equipment had to be considered. The solutionThe automation system for cardboard cutting plant operation planning solves these problems with the use of mathematical methods and optimization algorithms. The system functions include:

Results to dateThe use of the automation system enabled the plant operators to reduce the material losses from 5-6% to 2-3%, which amounts to saving of several hundred thousand dollars per year. Consideration of re-tuning of the finishing equipment in cutting equipment operation planning has remarkably reduced the number and duration of finishing equipment shutdown periods. The use of the automation system for plant operation planning has also noticeably reduced the production planning time. CustomersThe software system had been successfully installed at the following enterprises:

At the moment the software system is being installed at several industrial enterprises of Russia. Pdf version of this pageDownload pdf version of this page: ftp://pmasc.karelia.ru/pub/ASUP/GofraP/Gofra.zip "ASC: Corrugated cardboard" demoDownload "ASC: Corrugated cardboard" demo (in English): ftp://pmasc.karelia.ru/pub/ASUP/GofraP/CorrugatedSimpleCutDemoEng.exe Certificate of the Foundation of algorithms and software of the Russian Federal Agency for EducationFor the software system ASC has Certificate of the Foundation of algorithms and software of the Russian Federal Agency for Education: |

||||

|

|

ashabaev@psu.karelia.ru |